No, HACCP is not a SOP. HACCP stands for hazard analysis critical control points, which is a systematic approach to food safety, while SOP stands for standard operating procedure, which is a document outlining specific procedures for a particular task.

HACCP is a globally recognized system used to manage and prevent food safety hazards throughout the entire food production process. It involves identifying and evaluating potential hazards, establishing critical control points to control those hazards, and implementing monitoring procedures to ensure food safety.

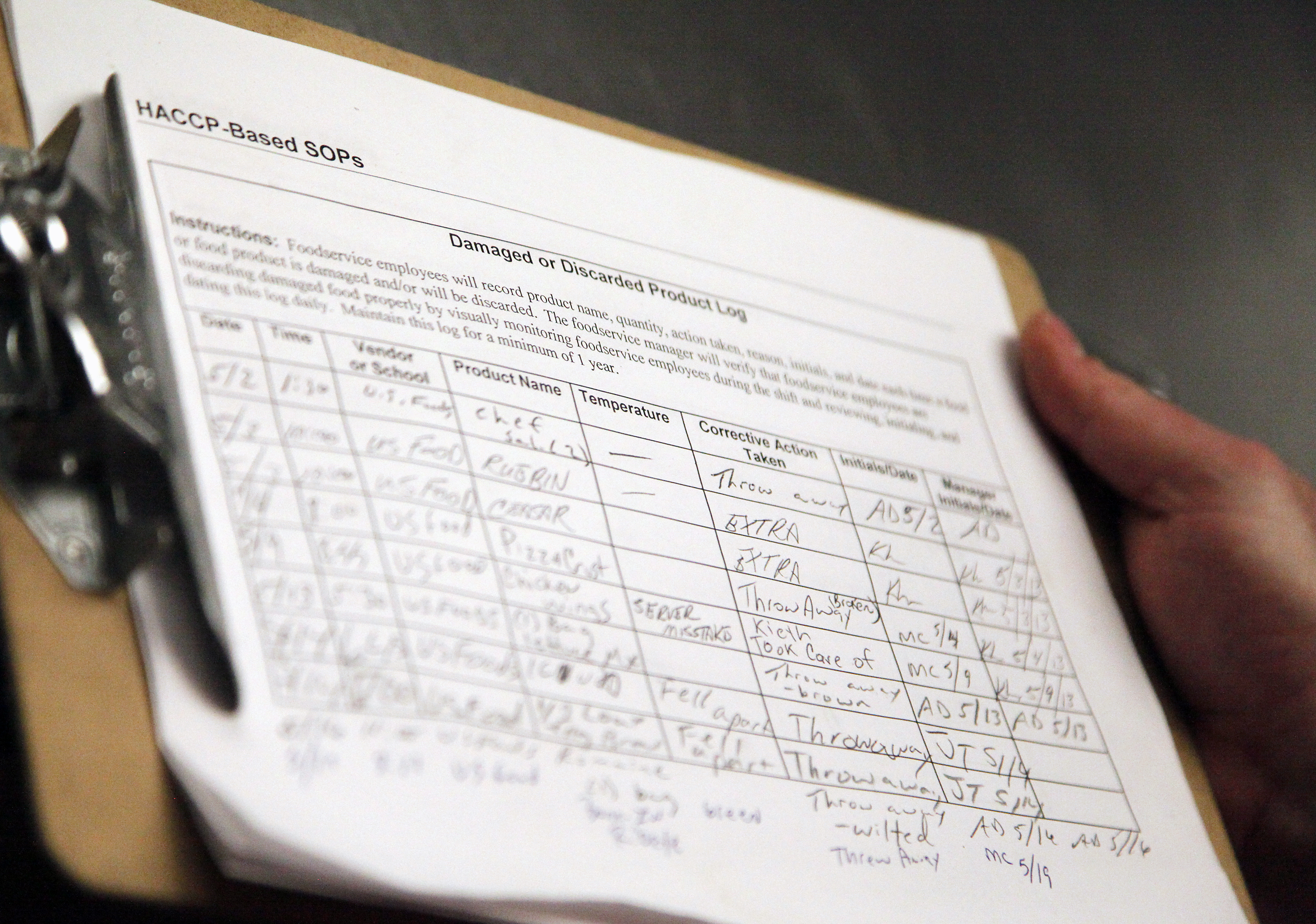

On the other hand, sops are detailed instructions that provide step-by-step guidance on how to carry out specific tasks or operations. They are typically developed to ensure consistency, efficiency, and quality in routine operations. While HACCP and sops both play important roles in ensuring food safety, they are separate approaches serving different purposes in the overall management of food safety.

Credit: www.pennlive.com

Understanding Haccp And Sop

HACCP (hazard analysis and critical control points) is not a standard operating procedure (sop). It is a systematic approach to food safety, designed to prevent hazards in food production. Haccp identifies potential risks, such as biological, chemical, or physical contaminants, and implements controls to mitigate them.

On the other hand, sops are detailed instructions that outline the specific steps and processes to be followed for a particular task. The purpose of HACCP is to ensure the safety of food products, while sops provide clear guidelines for employees to perform their tasks consistently.

By implementing HACCP and SOP, organizations can maintain food safety standards and reduce the risk of foodborne illnesses. Both HACCP and sops play a crucial role in ensuring the quality and safety of food products throughout the production process. So, while they are related, they serve different purposes in food safety management.

Key Differences Between Haccp And Sop

Haccp and sop have key differences regarding scope, application, focus, approach, and regulatory requirements. Haccp, which stands for hazard analysis critical control points, is a systematic preventive approach for food safety. It identifies, evaluates, and controls food safety hazards. Sop, on the other hand, stands for standard operating procedure, which is a set of step-by-step instructions to carry out routine operations in an organization.

The scope and application of HACCP are specific to food safety, whereas sop can be used in various industries for different procedures. Haccp focuses on identifying critical control points, while sop emphasizes standardizing operations. Furthermore, HACCP is a regulatory requirement in many countries, ensuring food safety at all stages of production, whereas sop may or may not be a mandatory requirement depending on the industry.

These distinctions highlight the importance of understanding the specific roles and applications of HACCP and sop in different contexts.

Haccp: A Scientific Approach To Food Safety

HACCP, which stands for hazard analysis and critical control points, is not a standard operating procedure (sop). Instead, it is a scientific approach to ensuring food safety. The principles of HACCP focus on identifying potential hazards, implementing control measures, and monitoring critical control points throughout the food production process.

By following the seven steps of HACCP implementation, food businesses can effectively manage risks and prevent contamination. From conducting a hazard analysis to establishing critical limits, monitoring procedures, corrective actions, verification, and record-keeping, HACCP provides a systematic framework for maintaining food safety.

It is not just a set of guidelines but a comprehensive approach that prioritizes prevention and continuous improvement. Implementing HACCP can help businesses demonstrate their commitment to food safety and meet regulatory requirements. Overall, HACCP offers a structured and scientific method to safeguarding the quality and integrity of food products.

Sop: Standard Operating Procedures

Haccp, hazard analysis critical control point, is not a standard operating procedure (sop), but rather a system that is used within an sop. Sops are vital in various industries as they provide a structured approach to carrying out tasks and ensure consistent quality.

In the food industry, for example, sops outline the specific steps to be followed for food preparation, handling, and storage, thereby minimizing the risk of contamination and ensuring the safety of consumers. Similarly, in manufacturing, sops detail the standardized processes for production, reducing errors and improving efficiency.

By creating effective sops, organizations can streamline their operations, enhance productivity, and maintain regulatory compliance. It is crucial to adhere to guidelines, begin sentences with varied phrases, and write in an SEO-friendly and human-like manner while keeping the content unique and plagiarism-free.

Overlap And Integration

Haccp and sop, although distinct, do overlap and integrate in certain areas. They both aim to ensure food safety and quality. When it comes to their intersection, HACCP focuses on identifying, evaluating, and controlling hazards, while sop provides step-by-step instructions for specific tasks.

These two systems complement each other by addressing different aspects of food safety management. Haccp identifies critical control points, whereas sop outlines the necessary procedures to maintain control. This integration ensures that all necessary precautions are taken to safeguard consumers from potential risks.

Their collaboration can enhance overall food safety protocols and prevent any potential hazards. Therefore, understanding the overlap and integration of haccp and sop is crucial for effective food safety management.

Haccp As A Part Of Sop

HACCP, which stands for hazard analysis and critical control points, is not strictly a standard operating procedure (sop). However, it can be incorporated into an sop to enhance food safety measures. By integrating HACCP principles into the sop, businesses can ensure comprehensive risk assessment and control throughout their processes.

This integration allows for the identification of critical points where hazards can occur and the implementation of preventive measures to mitigate those risks. The benefits of combining haccp and sop include improved food safety practices, increased efficiency in operations, and compliance with regulatory requirements.

By following these guidelines and incorporating haccp into their sop, businesses can establish robust food safety protocols that protect consumers and enhance their reputation in the industry.

Haccp Vs Sop: Which One To Use?

When considering the appropriate system for your industry, it is important to determine whether HACCP or sop is the best choice. Both have their own advantages and considerations to keep in mind. HACCP, or hazard analysis and critical control points, focuses on identifying and controlling potential hazards in the food industry.

On the other hand, sop, or standard operating procedures, provides a set of step-by-step instructions for carrying out specific tasks. Factors to consider when choosing between the two include the nature of your industry, the level of risk involved, and regulatory requirements.

By carefully evaluating these factors, you can make an informed decision that suits the needs of your business. Remember to prioritize safety, efficiency, and compliance.

Frequently Asked Questions

Is Haccp The Same As A Sop?

No, HACCP (hazard analysis and critical control points) is not the same as a sop (standard operating procedure). While HACCP focuses on identifying and controlling hazards in food production, sops are step-by-step instructions for executing specific tasks or activities. HACCP is a component of effective sops for food safety.

How Does Haccp Ensure Food Safety?

Haccp ensures food safety by identifying and controlling hazards that can affect the safety of food products. It follows a systematic approach of identifying critical control points, setting critical limits, monitoring, and implementing corrective actions. This proactive approach helps prevent foodborne illnesses and ensures that the final product is safe for consumption.

What Are The Seven Principles Of Haccp?

The seven principles of HACCP are: (1) conducting hazard analysis, (2) identifying critical control points, (3) establishing critical limits, (4) monitoring procedures, (5) implementing corrective actions, (6) verifying the system’s effectiveness, and (7) establishing record-keeping procedures. Adhering to these principles is essential for an effective HACCP program.

How Does Haccp Benefit The Food Industry?

Haccp benefits the food industry by providing a systematic approach to food safety. It helps identify and control potential hazards at key points in the production process, reducing the risk of contamination and ensuring consumer safety. By implementing HACCP, companies can demonstrate their commitment to producing safe and quality food products.

What Industries Should Implement HACCP?

Haccp should be implemented in industries involved in food production and processing, including but not limited to food manufacturing, food service establishments, catering companies, meat and poultry processing, seafood processing, dairy production, bakery and confectionery, and fruit and vegetable processing.

Following HACCP principles is crucial for ensuring food safety across various sectors.

Conclusion

It is clear that haccp (hazard analysis and critical control points) and sop (standard operating procedure) serve different purposes within the food industry. HACCP is a systematic approach to identifying and controlling potential hazards, while sops outline step-by-step instructions for specific tasks.

Though they are distinct, these two systems work together to ensure food safety and quality. Implementing both haccp and sops is crucial for any food business seeking to meet industry standards and regulations. Haccp provides a proactive strategy for preventing foodborne illnesses, while sops offer detailed guidelines for consistently carrying out essential processes.

By incorporating haccp and sops into daily operations, companies can minimize risks and ensure that food products are safe for consumers. It is essential to remember that these systems require continuous monitoring and regular updates to adapt to new challenges and changes in regulations.

Haccp and sops are both important tools that contribute to maintaining high standards of food safety. Their integration into a comprehensive food safety management system is essential for the success and reputation of businesses within the industry.

Leave a Reply